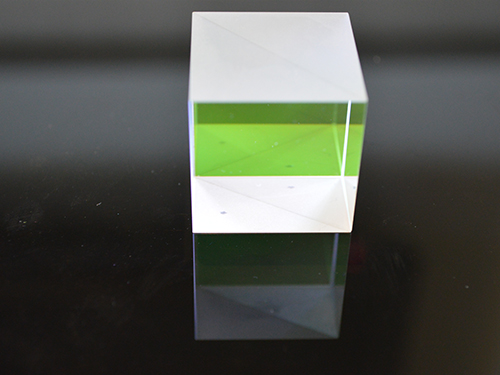

High power PBS cube

Polarization components are used to separate a beam of light into its orthogonal polarization states for isolation or routing. Our catalog includes both cube and plate polarizers designed to perform under a range of operating conditions, including high power, broad bandwidth, low dispersion, and high extinction. This is achieved using ion beam sputtered and e-beam dielectric coatings, some capable of greater than 1000:1 extinction ratio. When combined with our precision manufacturing, they result in laser quality plate polarizers with better than λ/8 transmitted wavefront error, and 10 – 5 surface quality.

Polarization components are used to separate a beam of light into its orthogonal polarization states for isolation or routing. Our catalog includes both cube and plate polarizers designed to perform under a range of operating conditions, including high power, broad bandwidth, low dispersion, and high extinction. This is achieved using ion beam sputtered and e-beam dielectric coatings, some capable of greater than 1000:1 extinction ratio. When combined with our precision manufacturing, they result in laser quality plate polarizers with better than λ/8 transmitted wavefront error, and 10 – 5 surface quality.

Capabilities

|

|

Standard & Semi-custom

|

|

Types

|

Plate, cube, Brewster angle

|

|

Materials

|

N-BK7, UV-grade fused silica, N-SF2

|

|

Dimensions

|

12.7 to 50.8 mm

|

|

Extinction Ratio

|

100:1 to 1000:1

|

|

Coatings

|

Laser line polarizing

Broadband polarizing

High energy

Wavelengths from 248 to 1300 nm

|

|

Quality

|

Standard and laser quality

|

|

Construction (cubes)

|

Optical adhesive contacting

Chemically activated direct bonding

Optical contacting

|

|

Surface Tolerances

|

Precision

|

Laser Quality

|

High Precision

|

|

Surface quality (scratch - dig)

|

20 - 10

|

10 - 5

|

5 - 1

|

|

Surface roughness (Å, RMS)

|

20

|

5

|

3

|

|

Flat Irregularity,

(P-V @ 633 nm before coating) |

λ/4

|

λ/10

|

λ/20

|

|

Dimensional Tolerances

|

Standard

|

Precision

|

High Precision

|

|

Length & width (mm)

|

+0.000 / -0.250

|

± 0.150

|

+0.000 / -0.010

|

|

Thickness (mm)

|

+0.000 / -0.250

|

± 0.150

|

± 0.005

|

|

Angular deviation

|

< 3 arc min

|

≤ 10 arc sec

|

≤ 0.5 arc sec

|

|

Clear Aperture

|

≥ 85%

|

≥ 90%

|

≥ 95%

|

|

Surface Tolerances

|

Precision

|

Laser Quality

|

High Precision

|

|

Surface Quality

(scratch - dig) |

40 - 20

|

10 - 5

|

5 - 2

|

|

Surface roughness (Å, RMS)

|

20

|

5

|

1

|

|

Surface Figure

(P-V @ 633 nm before coating) |

λ/2

|

λ/10

|

λ/25

|

|

Dimensional Tolerances

|

Commercial

|

Precision

|

High Precision

|

|

Diameter (mm)

|

+0.000 / -0.250

|

+0.000 / -0.100

|

+0.000 / -0.010

|

|

Length & width (mm)

|

± 0.050

|

+0.000 / -0.125

|

+0.000 / -0.010

|

|

Thickness (mm)

|

± 0.250

|

± 0.100

|

± 0.010

|

|

Angular deviation

|

< 5 arc min

|

≤ 1 arc sec

|

≤ 0.5 arc sec

|

|

Centration (ETV, mm)

|

0.05

|

0.01

|

0.005

|

|

Clear Aperture

|

≥ 85%

|

≥ 90%

|

≥ 95%

|

|

Spherical Tolerances

|

Commercial

|

Precision

|

High Precision

|

|

Spherical irregularity (P-V

@ 633 nm before coating) |

λ/2

|

λ/5

|

λ/100

|

|

Spherical radius (fringes)

|

5

|

3

|

0.5

|

|

Part No.

|

HPBS635-1064

|

HPBS127-1064

|

HPBS635-980

|

HPBS127-980

|

|

Wavelength

|

1064 nm

|

1064 nm

|

980 nm

|

980 nm

|

|

Reflection

|

>99.9%

|

>99.9%

|

>99.9%

|

>99.9%

|

|

Transmission

|

>97%

|

>97%

|

>97%

|

>97%

|

|

Extinction Ratio,

|

>1,000:1

|

>1,000:1

|

>1,000:1

|

>1,000:1

|

|

AR Coating

|

<0.20% per surface

|

<0.20% per surface

|

<0.20% per surface

|

<0.20% per surface

|

|

Surface Flatness

|

λ/10

|

λ/10

|

λ/10

|

λ/10

|

|

Wavefront Distortion

|

λ/8 transmitted

|

λ/8 transmitted

|

λ/8 transmitted

|

λ/8 transmitted

|

|

Reflected Beam

|

90°

|

90°

|

90°

|

90°

|

|

Scratch-Dig

|

10-5

|

10-5

|

10-5

|

10-5

|

|

Beam Deviation

|

< 5 arcmin

|

< 3 arcmin

|

< 3 arcmin

|

< 3 arcmin

|