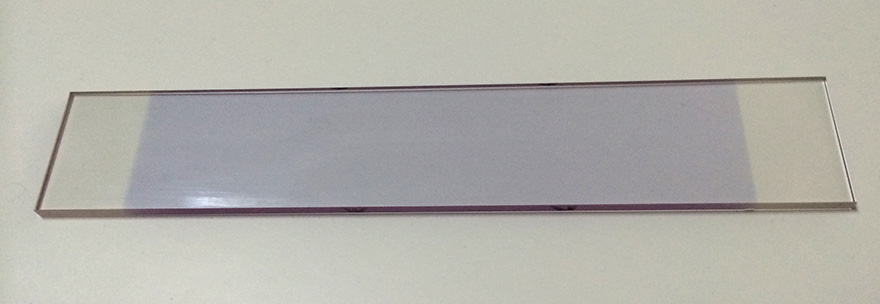

Diffusion Bonding Crystals

Diffusion Bonded Crystals (DBC) are crystals consisting of two, three or more parts with different doping levels or different doping, usually one laser crystal and one or two undoped crystals combined by optical contact and further bonded under high temperature.

Diffusion Bonded Crystals (DBC) are crystals consisting of two, three or more parts with different doping levels or different doping, usually one laser crystal and one or two undoped crystals combined by optical contact and further bonded under high temperature. Lasertec Inc is a leading manufacturer of finished composite crystal and glass components for solid-state lasers in China. We hold special diffusion bonding technology, which enables the joining of crystal materials without the use of an adhesive or an organic or inorganic bonding aid. This innovative technology reduces thermal lens effect of laser crystals, provides integral components to make compact lasers.

We are support below standard diffusion bonding crystals:

1. YVO4 diffusion bonding crystals

Based diffusion bonding technology YVO4 or GdVO4 components are extremely useful for higher power in YVO4-based laser systems. Undoped end-caps increase damage threshold by separating the pump input face with the lasing doped portion.

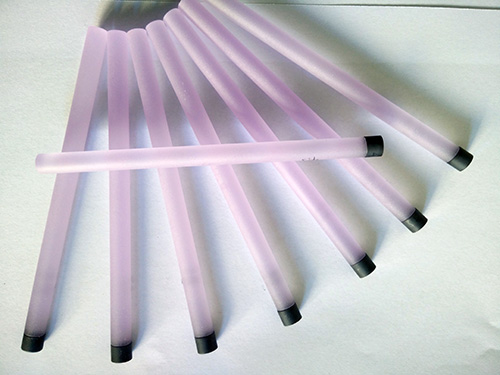

2.YAG diffusion bonding crystals

Based diffusion bonding technology microchips, especially in the form of Nd:YAG/Cr4+:YAG passively q-switched microchips have found a host of applications due to their compact size and the incorporation of both the lasing material and q-switch into a monolithic element. This approach minimizes system complexity and system size, and maximizes efficiency.

Based diffusion bonding technology microchips, especially in the form of Nd:YAG/Cr4+:YAG passively q-switched microchips have found a host of applications due to their compact size and the incorporation of both the lasing material and q-switch into a monolithic element. This approach minimizes system complexity and system size, and maximizes efficiency.

3. KTP and KTA diffusion bonding crystals

Lasertec offers the walk-off correction of non-linear crystals such as KTP through our bonding process. We possess the criteria to design walk-off corrected composites employing uniaxial and biaxial crystals. We can manufacture walk-off corrected composites according to customer specifications and are able to assist with the complete design of components or devices.

4. BBO with Z cut to increase the length to reduce half voltage in E-O Q-switch device.

Specification of DBC crystal

|

Dimensional Tolerance:

|

Diameter +/-0.1mm ,Length+/-0.5mm

|

|

Wavefront Distortion:

|

<λ/8 at 633nm per inch

|

|

Surface Quality:

|

20/10

|

|

Parallelism:

|

< 10 arc seconds

|

|

Perpendicularity:

|

< 5 arc minutes

|

|

Surface Flatness:

|

<λ/10 at 633nm

|

|

Clear Aperture:

|

Central 95%

|

|

Chamfer:

|

0.15X5°

|

|

Coating:

|

AR coating, HR coating

|

Standard Products

|

Part No

|

Material

|

Diameter(mm)

|

Coating

|

|

DBC-0001

|

NdYAG+CrYAG

|

3X3X10

|

S1:HR1064nm,HT808nm/S2:PR1064nm

|

|

DBC-0002

|

NdYAG+CrYAG

|

Dia6.35X105

|

S1:HR1064nm,HT808nm/S2:PR1064nm

|

|

DBC-0003

|

NdYAG+YAG

|

3X3X10

|

AR/AR1064&808 nm

|

|

DBC-0003

|

NdYAG+YAG

|

4X4X15

|

AR/AR1064&808 nm

|

|

DBC-0004

|

YAG+YbYAG+YAG

|

3X3X10

|

AR/AR1064&1030&808 nm

|

|

DBC-0005

|

NdYVO4+YVO4

|

3X3X10

|

AR/AR1064&808 nm

|

|

DBC-0006

|

NdYVO4+YVO4

|

4X4X10

|

AR/AR1064&808 nm

|

|

DBC-0007

|

NdYVO4+YVO4

|

3X3X12

|

AR/AR1064&808 nm

|

|

DBC-0008

|

YAG+NdYAG+YAG

|

3X3X10

|

AR/AR1064&808 nm

|

|

DBC-0009

|

KTP+KTP

|

5X5X20

|

AR/AR1064&1570 nm

|

|

DBC-0010

|

KTP+KTP

|

10X10X20

|

AR/AR1064&1570 nm

|

|

DBC-0011

|

BBO+BBO

|

3X3X40

|

AR/AR1064nm

|

|

DBC-0012

|

UVFS+UVFS

|

N/A

|

Customized

|

|

DBC-0013

|

YAG serial

|

N/A

|

Customized

|